product description

K2 HF - High Fusing

K2 HF is a high-fusing metal ceramic with excellent optical and physical properties. It is fired at 910°C and is suitable for almost all alloys with a CTE of 13.8 - 14.9 / 25° - 500°C. If the CTE is higher than 14.5, long-term cooling is recommended.

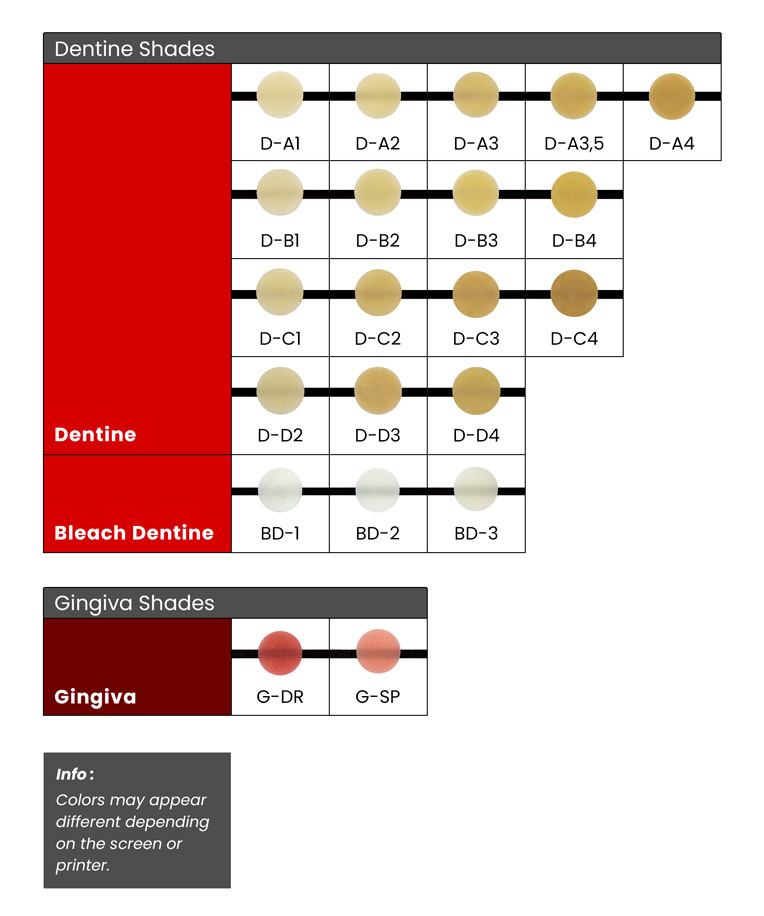

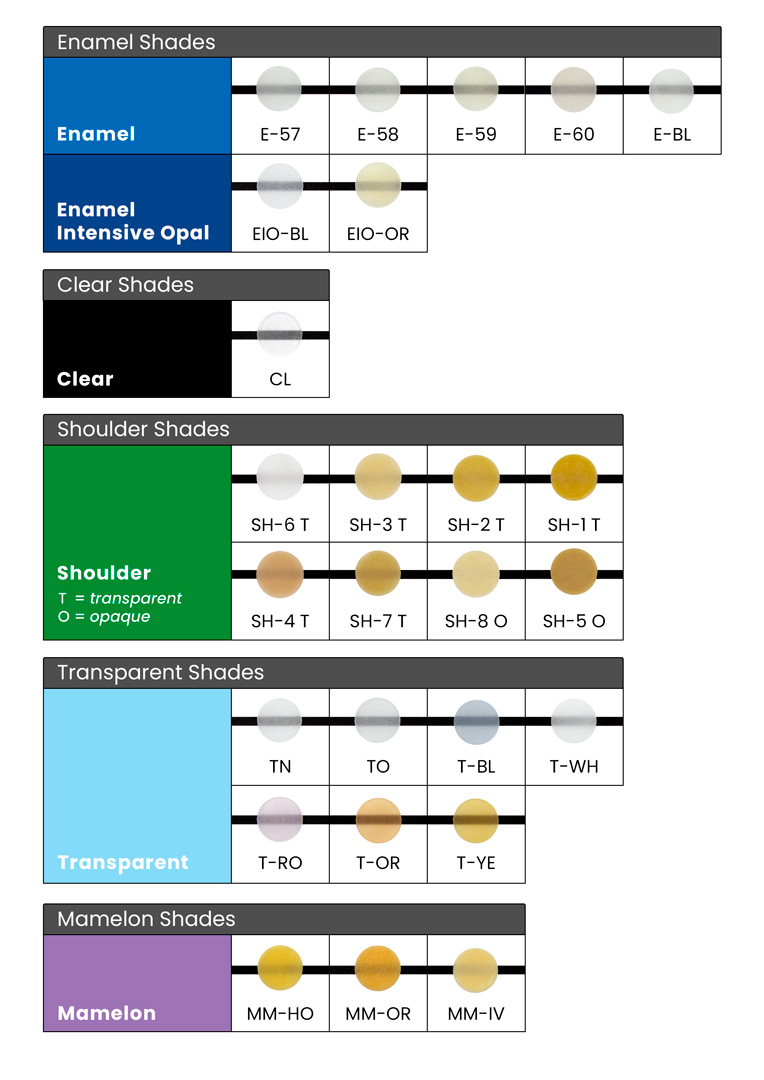

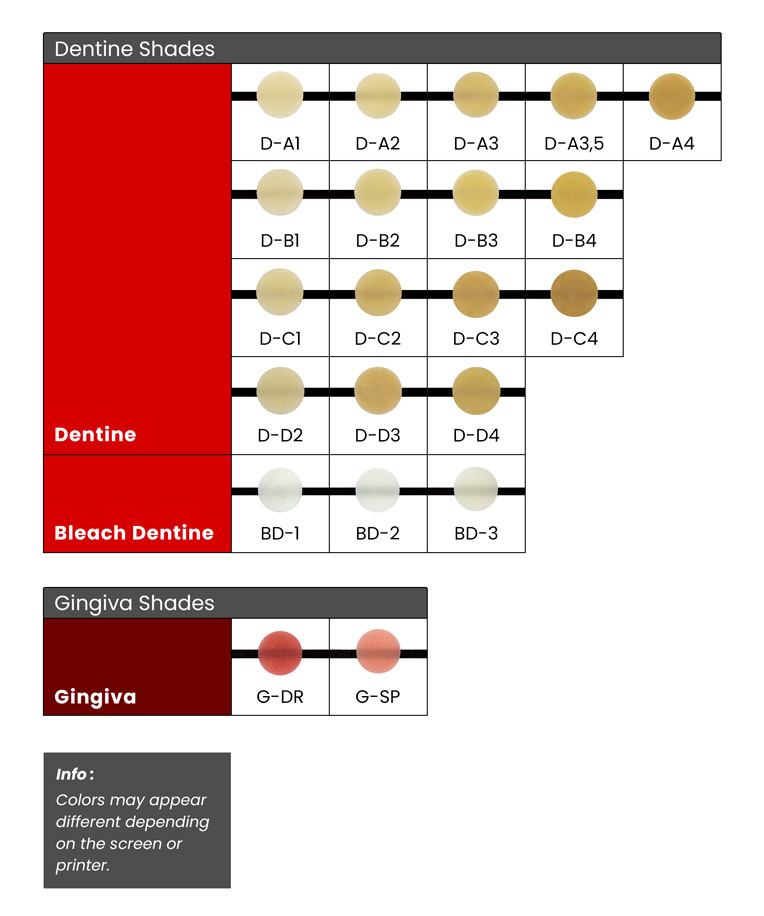

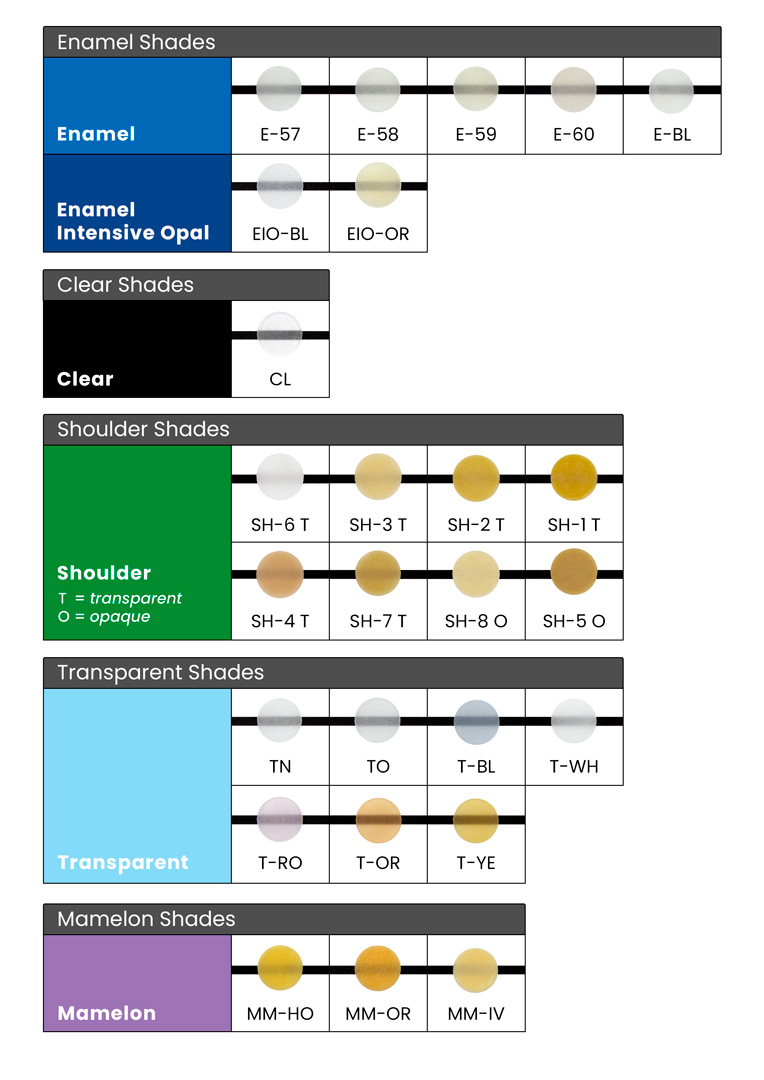

Shades overview

Firing parameters K2 HF | |||||||

| starting temperature | dry | increase temperature | vacuum | final temperature | hold time | result | |

| Oxid brand | Depending on the alloy manufacturer‘s instructions | ||||||

| Bonder brand | Recommended for non precious metal! When using bonder only 1 opaque firing is necessary! | shiny | |||||

| 550°C / 1022°F | 6 min | 80°C (176°F) / min | + | 980°C / 1796°F | 1 min | ||

| 1. Opaque firing powder* | 590°C / 1094°F | 4 min | 75°C (167°F) / min | + | 950°C / 1742°F | 1 min | shiny |

| 2. Opaque firing powder | 590°C / 1094°F | 4 min | 75°C (167°F) / min | + | 940°C / 1724°F | 1 min | slightly shiny |

| Shoulder firings | 550°C / 1022°F | 4 min | 80°C (176°F) / min | + | 930°C / 1706°F | 1 min | slightly shiny |

| Dentin firing | 570°C / 1058°F | 6 min | 50°C (122°F) / min | + | 910°C / 1670°F | 1 min | slightly shiny |

| Correction firing | 570°C / 1058°F | 5 min | 50°C (122°F) / min | + | 900°C / 1652°F | 1 min | slightly shiny |

| Glaze firing | 590°C / 1094°F | 3 min | 50°C (122°F) / min | - | 895°C / 1643°F | 1 min | shiny |

| Glaze firing with glaze | 500°C / 932°F | 3 min | 45°C (113°F) / min | - | 855°C / 1571°F | 1 min | shiny |

| * For non precious alloys final temperature 960°C Firing Parameters are Guidelines and need to be adjusted to the situation of the furnace! The right firing result is important! | |||||||

| Changes and errors excepted! | |||||||

Downloads

| Manual 2.0 | Shades | Manual Multi Language |

| Safety data sheet 1.0 | Opacity values 2024 |