Description du produit

Digi E Mill 3

Le nouveau Digi E Mill 3 vous permet d'automatiser l'ajustage précis des appareils occlusaux. Vous pouvez vous attendre aux meilleurs résultats en peu de temps sans travail fastidieux. La fabrication usinée assure également une qualité constante élevée.

DONNÉES TECHNIQUES

| GENERAL | |

|---|---|

| Fields of application | Dry machining |

| Materials | Thermo-formed plastic foil |

| Indications | Aligners and other splints |

| Holder systems | Holder for tool-free clipping in of the aligners |

| BASIC SYSTEM | |

|---|---|

| Construction | Sturdy aluminum structure |

| Housing | White high-gloss lacquer finish · upward opening lift door to the workroom |

| Number of axes | 3+1 |

| Linear axes X-/Y-/Z-axis | X-axis: rack and pinion drive · Y-/Z-axis: trapezoidal screw spindles · motor resolution 10 μm · max. axial backlash 0.06 mm |

| Rotary axis B-axis | Rotation angle: 360°, infinite |

| Control unit | Control electronics with continuous path progression and dynamic pre-calculation · hardware-based real-time operating system with standardized instruction set · FPGA-integrated processor · updateable hardware · real-time path and ramp calculation via dedicated hardware engines in the FPGA · four-quadrant control of the motors for particularly smooth running · multiple digital I/Os for controlling the peripherals · integrated inverter for synchronous and asynchronous motors, electronic gate detection · Ethernet and USB interface |

| Lighting | RGB LED lighting with status indication |

| SPINDLE | |

|---|---|

| General | High-frequency spindle with mechanical tool change |

| Speed | Up to 60,000 RPM |

| Power | Peak power (Pmax): 800 watts · continuous power (S1): 450 watts |

| Bearing | 2-fold hybrid ceramic ball bearing |

| Collet | Collet type ER8 for tools with 3 mm shank diameter |

| PROCESSING MODES | |

|---|---|

| Dry | Compressed air-free operation without suction |

| CONNECTION REQUIREMENTS | |

|---|---|

| Compressed air | – |

| Power supply | 100–240 volts · 50/60 Hz, 320 watts |

| Extraction System | – |

| Data | 10/100/1000 MBit/s BaseT port (auto-sensing) Ethernet via RJ-45 socket |

| ENVIRONMENTAL CONDITIONS | |

|---|---|

| Operating temperature | Between 10 °C and 35 °C |

| Air moisture | max. 80 % (relative), non-condensing |

| APPROVALS | |

|---|---|

| All models | CE |

| North America model | UL 61010-1, CAN/CSA C22.2 No. 61010-1 |

| DIMENSIONS & WEIGHTS | |

|---|---|

| Dimensions (W/D/H) | 360 × 370 × 490 mm with closed door · 360 × 420 × 490 mm with open door |

| Footprint (W/D) | 286 × 268 mm |

| Weight | 25 kg |

| SCOPE OF DELIVERY | |

|---|---|

| CAM Software | TRIMCAM software for aligner production included in the scope of delivery |

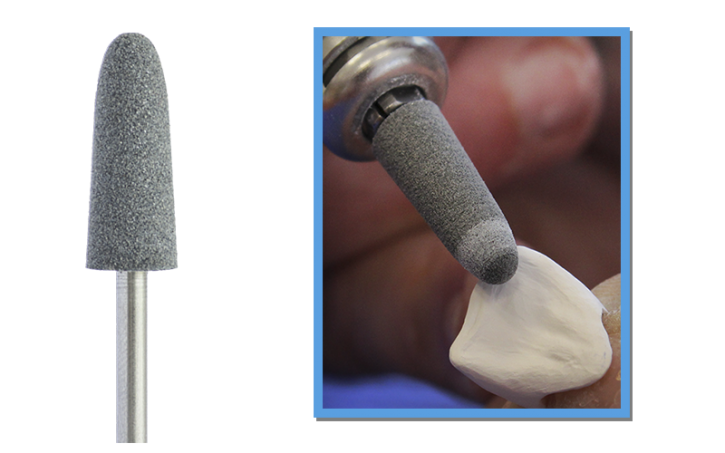

| Accessories | Calibration set incl. stirrup measuring screw · Torx driver · torque driver 1.5 Nm · cleaning brush · cleaning scrubber and microfiber cloth · radius cutter (2 pcs.) · clamping wrench · open-end wrench · power cable · Ethernet network cable |

Sous réserve de modifications et d'erreurs.